Bricks are rectangular units of construction material. Bricks are used in masonry construction, walls, and pavements. It is used as a substitute of stone, where the stone is not readily available. Brick chips are often used as coarse aggregate in the concrete mix.

Percentage of Constituents of Brick (Weight Basis)

There are six major ingredients of brick. The general percentage of these ingredients in brick is given below:

Ingredient |

Percentage in brick |

| Silica (SiO2) | 55% |

| Alumina (Al2O3) | 30% |

| Iron Oxide (Fe2O3) | 8% |

| Magnesia (MgO) | 5% |

| Lime(CaO) | 1% |

| Organic Matter | 1% |

Chief Ingredients of Brick and Their Functions

Silica (Sand) and Alumina (Clay), these two are the most prominent ingredients in brick clay. When mixed with water in proper proportions, it gains plasticity. The plastic mass can be easily molded and dried. It should not go through cracking, shrinkage or warping.

Alumina

Alumina is the main constituent of clay. It acts as a cementing material in raw brick. Brick clay is plastic due to the presence of alumina. This plasticity ensures that bricks can be molded. An excess amount of alumina in clay may cause the bricks to shrink, warp or crack on drying and burning as any other cementing material.

Silica

Good quality bricks contain 50-60% silica. It is present in both free and combined form. As frees sand, it remains mechanically mixed with clay. In combined form, it reacts with alumina to form aluminosilicates. Silica prevents raw bricks from cracking, shrinking and warping. The higher the proportion of sand, the more and shapely and uniform in texture will be the brick. Although, excess silica destroys cohesion between the brick clay particles and makes brick brittle and weak. The durability of bricks largely depends upon the proper proportion of silica and alumina.

Lime

Bricks should contain a little amount of finely powdered lime. It enables silica (of a required portion) to melt at the furnace temperature of 1650oC and binds the particles of brick together resulting in strong and durable bricks. At about 1100o C, lime acts as a catalyst to elevate the furnace temperature to 1650oC at which silica fuses. This slightly fused silica works as a strong cementing material. Excess lime in brick clay will cause vitrification of bricks. It causes bricks to melt, as more than the required amount of silica will fuse. The bricks then lose their shape and become disfigured.

Iron Oxide

Bricks contain a small quantity of Iron Oxide. Iron Oxide acts a flux like lime, thus helps silica to fuse at low temperature. It imparts a red color to bricks upon burning. Iron also increases the durability and impermeability of the bricks.

Magnesia

A small proportion of magnesium decreases shrinkage and gives a yellow tint to the bricks. An excess amount of it causes bricks to decay.

{adselite}

Harmful Ingredients of Brick

Lime

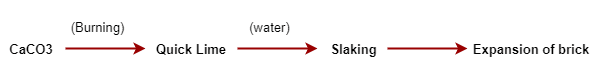

Excess lime melts the bricks and disfigures it. If CaCO3 exists (in the purest form, i.e., if it contains at least 95% CaO) in lime-lump in brick clay, it converts into quicklime on burning. When these bricks come in contact with water, quicklime slakes and expands. And causes disintegration of bricks.

Alkalis

Alkalis are mainly salt of Sodium (Na) and Potassium (K). It acts as a flux in the kiln and causes fusion, warping, and twisting of bricks. Alkalis absorb moisture from the atmosphere and cause dampness & efflorescence in bricks (because of the presence of hygroscopic salts, e.g., CaCl2, MgCl2, etc.).

Pebbles, Stones & Gravels

Their presence does not allow thorough mixing of earth, thus the bricks produced are weaker. Such bricks cannot be broken at the desired section and they break very irregularly.

Iron Pyrites (FeS)

Iron Pyrites causes crystallization & disintegration of bricks while burning. It discolors bricks in the form of black slag.

Organic Matter

Organic matter in bricks makes bricks porous resulting in low density and weaker bricks.

References

- Singh, G, 1996, Building Materials. 3rd ed. Standard Publishers Distributors. Delhi, India.

- Aziz, M.A. 1973. A Text Book of Engineering Materials. University Campus. Dhaka, Bangladesh.

Brick Related Articles

- What is brick?

- Types of Bricks

- Composition of Bricks

- Characteristics of Good Bricks.

- Uses of brick.

- Compressive Strength of Brick

- Density of Brick

- Thermal Conductivity of Brick

- Advantages and Disadvantages of Hoffmann kiln.

- What is Refractory or Fire Bricks? Types, Composition

- Properties of Good Refractory Bricks

- Uses of Refractory Bricks

- Lime Pitting

Keywords: