Ribbed or waffle slab is a slab system which consists of series of parallel reinforced concrete T beams framing into reinforced concrete girders. The slab is the flange of the beam and the extended part is the web. The extended part is known as ribs. The spacing between the ribs should be in general 20-30 inch. The ribs are tapered in cross-section in its lower part.

Types of Ribbed and Waffle slabs

There are two types of ribbed slab system

- One way ribbed slab system

- Two-way ribbed slab System (Waffle system)

A brief description of these types are given below:

One-way Ribbed Slab System

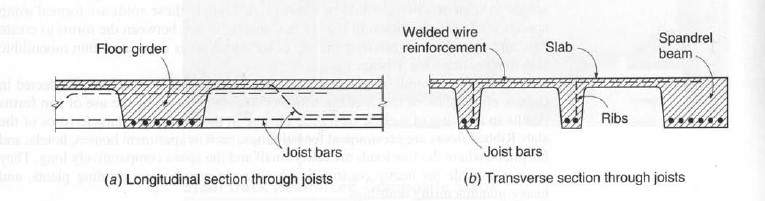

A one-way joist floor slab consists of a series of small, reinforced concrete T beams that are connected with girders that in turn carried by the building column. T beams are known as joists which are formed by setting steel pan at a constant spacing. Concrete is cast between those spacing to make those ribs and in this way, the slab also cast and the slab becomes the flange of T beam.

Two-way Ribbed Slab System (Waffle System)

The system was designed to decrease the weight of traditional full-concrete slabs. The dome-shaped forms create a matrix of voids surrounded by orthogonal ribbing, producing a two-way configuration very suitable for large-spanning slabs. Voids between all the domes reduce the dead load as the width of that portion of the slab is less than a flat slab. This type of slab is known as waffle slabs because they look like waffles with rows of beams running underneath them. Waffle slab shows a ceiling which is suitable to install all the electrical appliances and can give a better outlook thus increasing the aesthetic factor.

Advantages of Ribbed and Waffle Slabs

- In this type of slab, the tension stress is eliminated in the tension side of the slab. The strength of concrete in tension is very small and so elimination of much of the tension concrete is done by the use of pan forms.

- Economical where the live loads are fairly small such as apartment houses, hotels.

- Long slab spans can be constructed through ribbed and waffle Slabs. In many cases, long spans are desirable in the building. Ribbed or waffle slabs are an easy solution for this purpose.

- Provide architectural advantages. All the Electrical appliances can be installed easily in the gap of the ribs which can be architecturally aesthetic.

- Slab thickness of ribbed or waffle slabs is less than other slab systems. Therefore the weight of slab is reduced. This saving of weight can change in structural characteristic.

- Lighter and stiffer slab than an equivalent flat slab.

- Reducing the extent of foundations by reducing the ultimate load.

- They provide a very good form where slab vibration is a viable issue. {adselite}

Disadvantages of Ribbed and Waffle Slabs

- Not suitable where the live loads are huge as heavy manufacturing buildings, warehouses.

- The thickness of the slab is controlled as the requirement of fire resistance.

- Formwork cost is high.

- Sometimes difficult to install the electric equipment.

References

- Design of Concrete Structures 14th Edition By H.Nilson