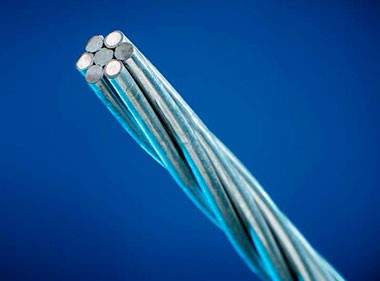

Pre-stressed concrete is a form of concrete where initial compression is given in the concrete before applying the external load so that stress from external loads is counteracted in the desired way during the service period. This initial compression is introduced by high-strength steel wire or alloys (called ‘tendons’) located in the concrete section.

Why is Prestressed Concrete Required?

Now, the question is, why do we need this complexity?

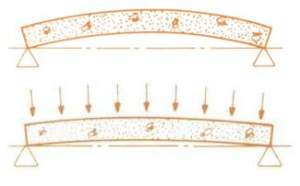

Okay, before getting started let’s go back to some basics first. We know, concrete is good at compression but very weak in tension. And so we see after external loading, in the bottom part of the concrete, a tension zone occurred. So, it tries to be elongated, and guess what? It cracks. This is why we add some steel bars at the bottom section so that it can resist most of the tension and save concrete from cracking. This is our traditional RC structure. But what about some megastructures with larger beam spans? Think about a flyover or the famous Gateway Bridge in Australia, Incheon Bridge in South Korea, or Ringhals nuclear reactor in Sweden where external loading is very high.

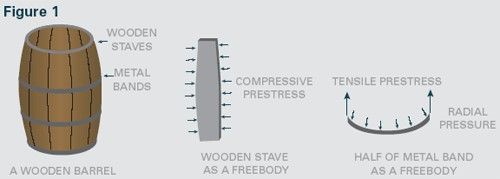

In the way of a traditional RC structure, for these larger beam spans, we should provide a larger depth which is often too much that, for a bridge over a river, there will be not enough space under the bridge for ships to pass it. Here comes this new concept--- Pre-stressed concrete. The concept of prestressed concrete is not so difficult. In fact, the practice of prestressing things is very older in our day-to-day life. Imagine a barrel made of wooden staves and metal bands. Tung-Yen Lin, a civil engineering professor at the University of California, explained it in the introductory chapter of his book “Design of Prestressed Concrete Structures".

The basic principle of prestressing was applied to construction, perhaps centuries ago, when ropes or metal bands were wound around the wooden staves to form a barrel (see Figure 1). When the bands were tightened, they were under tensile prestress, which in turn created compressive prestress between the staves and enabled them to resist hoop tension produced by internal liquid pressure. In other words, the bands and the staves were prestressed before they were subjected to any service loads.

Like this, in prestressed concrete, initial compression is given to be balanced by future loading that will create tension.

How does Pre-Stressed Concrete Work?

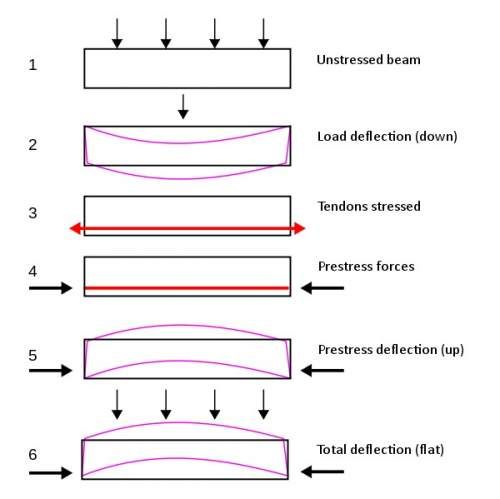

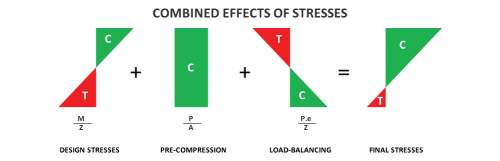

So by now, I have had our concept. We have learned why and when we should use prestressed concrete. So, how does it work? In the real life, high tensile strength steel wires are inserted into the beam section and they are stretched and anchored, then released. Now the steel tendon wants to gain its original length and tensile stresses are transformed into compressive stress in the concrete. Now after loading there are two kinds of forces on the beam,

- Internal prestressing force

- External forces (Dead load, Live load, etc.)

Which must counteract each other. Observing the moment diagram, we will find something like this

{adselite}

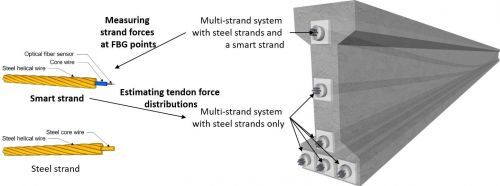

Pre-Stressed Concrete Materials

According to AASHTO, high-strength seven-wire strands, high-strength steel wire, or alloys of grade and type (as specified by the designer) should be used in prestressed concrete. Also, stronger concrete is required in prestressed than normal RC. Generally, minimum 28-day cylinder strength of 5000 psi concrete must be used. So, why this high-strength concrete? Well, if the concrete is not strong enough, it can be cracked or failed when it is stressed by tendons. As well as high compressive strength offers higher resistance to tension and shear and so it is desirable for prestressed concrete.

Moreover, high-strength concrete is less subjected to shrinkage cracks. It has a higher modulus of elasticity and smaller creep strain. As a result, the loss of prestressing is small.