Concrete is a mixture of several materials. At the hardened state, this heterogeneous material becomes stone-like mass. The extensive use of concrete in the construction field has made it a material of huge concern for engineers. To participate in the vast uses of concrete an engineer must know its properties. Here in this article, we have provided a glimpse of the properties of concrete.

Strength

Strength of concrete are of the following types:

- Compressive strength

- Tensile strength

- Flexural strength

- Shear strength

Compressive Strength

Two types of test specimens are used in Bangladesh -(1) Cube and (2) Cylinder.

The cube specimens of concrete of the desired proportion are cast in steel or cast iron molds, normally 6-inch cube. The standard cylinder specimen of concrete is 6 inch in diameter and 12 inches in height and cast in a mold generally made of cast iron;

Standard cubes and cylinders are tested at prescribed ages, generally, 28 days, with additional tests often made at 1, 3, and 7 days. The specimens are tested for crushing strength under a testing machine. The cube tests give much greater values of crushing strength, usually 20 to 30 % more than those given by cylinders.

According to British standard, the strength of a cylinder specimen is equal to three-quarters of the strength of the cube specimen.

(Source:https://www.fhwa.dot.gov/publications/research/infrastructure/structures/06103/chapt3.cfm)

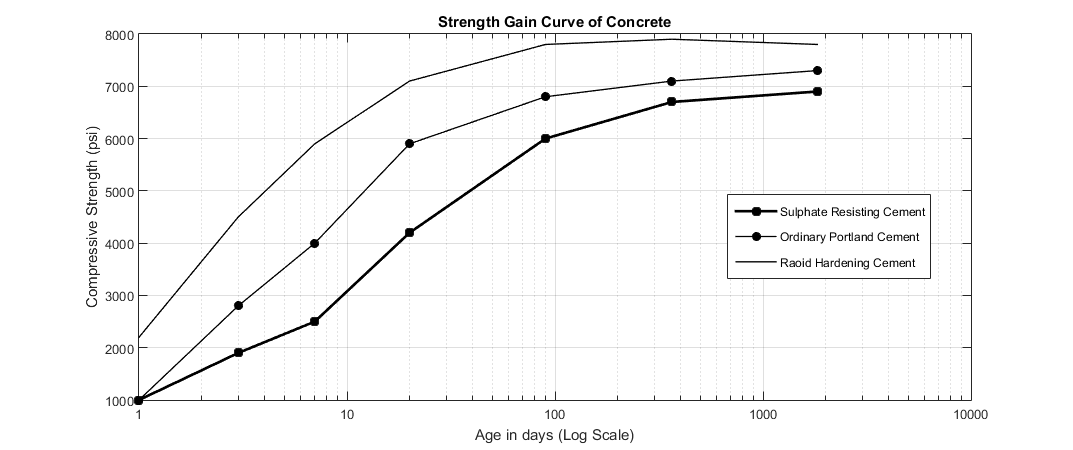

Effect of age on concrete strength:

Concrete attains strength with time. Ordinary cement concrete gains above 70 to 75% of its final strength within 28 days and about 90 to 95 % in the course of one year. It is often desirable to check the suitability of a concrete long before the results of the 28-day test are available. When no specific data on the materials used in making concrete are available, the 28-day strength may be assumed to be 1.5 times of the 7 days’ strength. Tests have shown that for concrete made with ordinary Portland cement the ratio of the 28 days to 7 days’ strength generally lies between 1.3 to 1.7, and the majority of the results fall above 1.5. The extrapolation of 28 days’ strength from the 7 days’ strength is, therefore quite reliable;

The rate of gain of strength of the different type of cement concretes are shown in the figure below

Tensile strength

Concrete is very weak in tension. The tensile strength of ordinary concrete ranges from about 7 to 10 percent of the compressive strength.

Flexural strength

The flexural strength of plain concrete is almost wholly dependent upon the tensile strength. However, experiments show that the modulus of rupture is considerably greater than the strength in tension.

Shear strength

It is the real determining factor in the compressive strength of short columns. The average strength of concrete in direct shear varies from about half of the compressive strength for rich mixtures to about 0.8 of the compressive strength for lean mixtures.

{adselite}

Workability

The strength of concrete of a given mix proportion is very seriously affected by the degree of its compaction. It is therefore vital that the consistency of the mix be such that the concrete can be transported, placed and finished sufficiently easily and without segregation. A concrete satisfying these conditions is said to be workable.

Factors affecting the workability of concrete are:

- Water Content

- Mix Proportions

- Size of Aggregates

- Shape of Aggregates

- Grading of Aggregates

- Surface Texture of Aggregates

- Use of Admixtures

- Use of Supplementary Cementitious Materials

- Time

- Temperature

Usually, Slump test is done to indirectly determine the workability of a concrete mix.

Elastic Properties

Concrete is not perfectly elastic for any range of loading, an appreciable permanent setting taking place for even low loads. The deformation is not proportional to the stress at any stage of loading. The elastic properties of concrete vary with the richness of the mixture and with the intensity of the stress. They also vary with the age of concrete.

Durability

Durability is the property of concrete to withstand the condition for which it has been designed, without deterioration over a period of years. Lack of durability can be caused by external agents arising from the environment or by internal agents within the concrete.

Causes can be categorized as physical, mechanical and chemical.

Physical cause arises from the action of frost and from differences between the thermal properties of aggregate and of the cement paste, while mechanical causes are associated mainly with abortion.

Impermeability

Penetration of concrete by materials in solution may adversely affect its durability, for instance, when Ca(OH)2 is being leached out or an attack by aggressive liquids (acids) takes place. Permeability has an important bearing on the vulnerability of concrete to water and frost. In the case of reinforced cement concrete, the penetration of moisture and air will result in the corrosion of steel. This leads to an increase in the volume of the steel, resulting in cracking and spalling of the concrete. Permeability of concrete is also of importance for liquid retaining and hydraulic structures;

Segregation

The tendency of separation of coarse aggregate grains from the concrete mass is called segregation. It increases when the concrete mixture is lean and too wet. It also increases when rather large and rough-textured aggregate is used. The phenomenon of segregation can be avoided as follows.

- Addition of little air-entraining agents in the mix.

- Restricting the amount of water to the smallest possible amount.

- All the operations like handling, placing and consolidation must be carefully conducted.

- Concrete should not be allowed to fall from large heights.

Bleeding

The tendency of water to rise to the surface of freshly laid concrete is known as bleeding. The water rising to the surface carries with it, particles of sand and cement, which on hardening form a scum layer is popularly known as laitance. Concrete bleeding can be checked by adopting the following measures.

- By adding more cement

- By using more finely ground cement

- By properly designing the mix and using the minimum quantity of water

- By using little air entraining agent

- By increasing the finer part of fine aggregate

Fatigue

Plain concrete when subjected to flexure, exhibits fatigue. The flexure resisting ability of concrete of a given quality is indicated by an endurance limit whose value depends upon the number of repetitions of stress. In concrete pavement design, the allowable flexural working stress is limited to 55% of the modulus of rupture.

References

- Neville, A. and Brooks, J. (1990). Concrete technology. 2nd ed. Harlow, Essex, UK: Longman Scientific & Technical.

- Aziz, M. A.(1973). A Text-Book of Engineering Materials. Dhaka, Bangladesh: University Campus